The scope of this project is to delineate a novel stent prototype based on a new hybrid bioresorbable polymer and magnesium material that is non-pharmacological, non-toxic and mechanically stable with deterioration that can be an alternative to a metal or polymer stent without drugs. In conjunction with that a new stent design will be made that will be made using cutting-edge technology like 3D printing, which has never before been used to develop metal-polymer stents and which will have major advantages in the field, like speed, customisation, reducing complex surgery, etc.

The novel stent design will be made based on the mechanical properties (Young’s modulus, hardness, radial strength) and the metal-polymer material to be able to determine the lengths, diameters and widths of the arms and joints of the stent. Based on the parametric study, various simulations will be carried out to see the viability of the alternative designs that may be obtained.

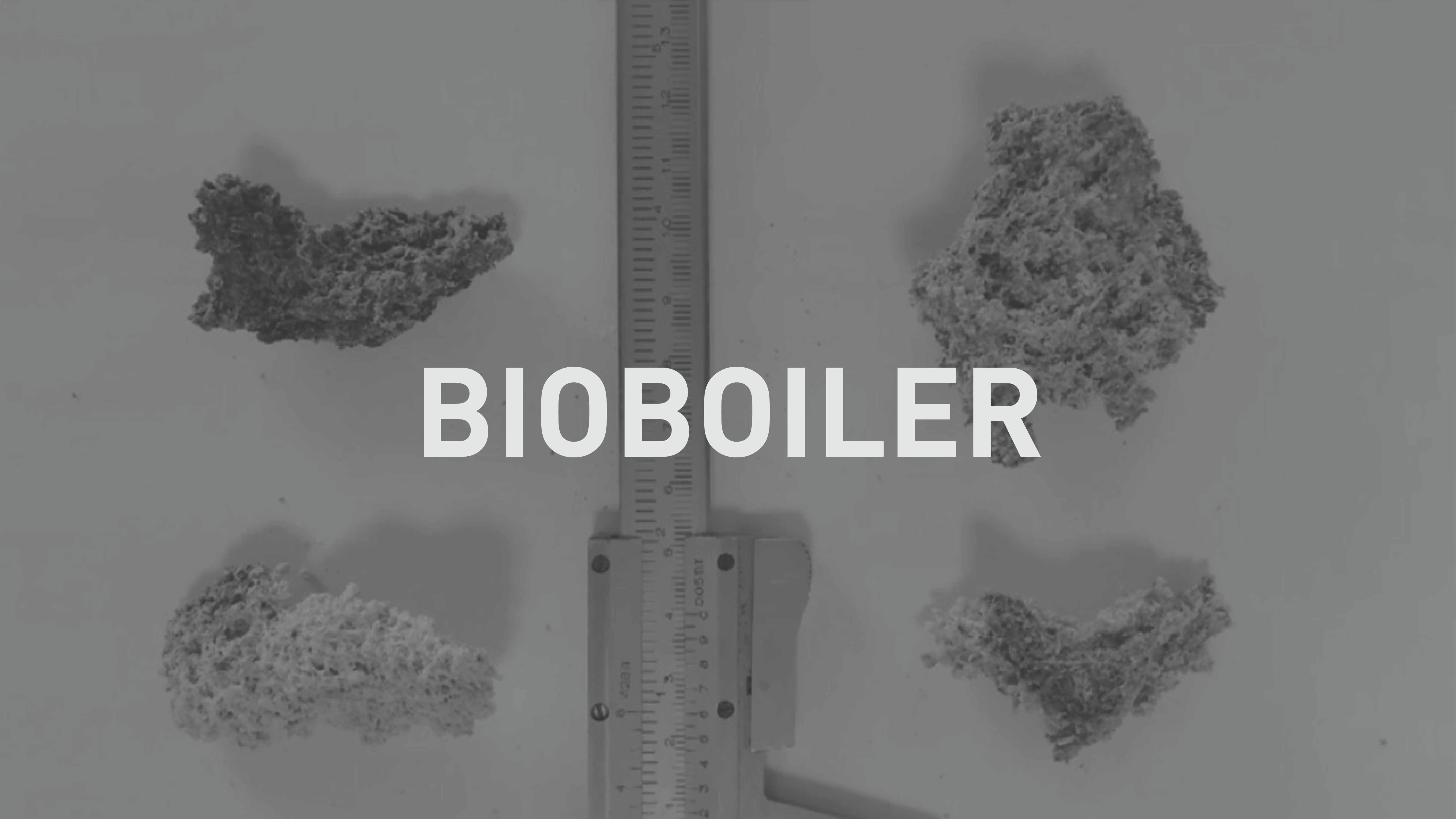

In the first year progress has been made in developing materials for 3D printing with both FDM (Fused deposition modelling) and SLA (stereolithography), and in conditioning the printers for making stents (small devices with a lot of detail that require high resolution and are a challenge in the printing process). Furthermore, a computational tool has been created that can analyse and characterise the stents and provide detailed information about the influence of each parameter and specific design information about the device’s behaviour.

The tool can be used for optimising the device after the final design has been chosen, the material has been characterised and the printer has been conditioned. The first stent prototypes have been printed successfully with new materials developed in the project. In light of the work done and the results obtained, we believe it is necessary to go deeper into developing the material until a final product is obtained that satisfies the demands of this application during the second year.