REDUCENANO 2.0

Validating a chemical process for reducing stable metal nanoparticles using metal oxide nanoparticles produced using flame spray pyrolysis as a raw material

Links:

Validating a chemical process for reducing stable metal nanoparticles using metal oxide nanoparticles produced using flame spray pyrolysis as a raw material

Links:

Powder metallurgy is a process for shaping metal in which powdered metal is used in a compacting process under controlled atmospheric and temperature condition. It is a field in constant evolution that makes it possible to develop metal materials with optimised properties using different procedures. Because of their unique properties, those materials can have applications in countless cutting edge industries like, for example, the automotive industry where new materials that are much stronger and lighter can be developed that, among many other options, help improve the efficiency and functionality of electric vehicles, as well as their positioning on the market. New lighter and stronger materials would improve the efficiency of current electric vehicles or battery performance, for example. That would translate directly into reducing the current dependency on fossil fuels.

However, the technique of powder metallurgy has certain limitations, like using materials with high purity and a high cost, as well as the segregation processes, multiple crystalline phases, the large number of voids or the formation of interstitial compounds that impede obtaining certain complex and homogenous materials with optimum mechanical properties. Because of that, the REDUCENANO 2.0 project focused on developing multipurpose technology that can be used to obtain metal nanoparticles with different optimised compositions that can be used in powder metallurgy to develop new lightweight nanomaterials that can improve electric vehicles. Metal nano-oxides were used to develop effective reduction processes.

To achieve those goals, LUREDERRA and UPNA set the following goals.

➢ Readjust the production method of nanostructured metal oxides with a structural distribution optimal for the desired composition, and complete the production of specific formulations encompassed by iron, nickel, aluminium and magnesium systems using Flame Spray Pyrolysis (FSP) technology

➢ Develop, evaluate and validate new more efficient and sustainable reduction processes that create a path to obtaining raw materials for metallurgy with better properties

➢ Lower the costs of the processes of obtaining and preparing raw materials to be used in the powder metallurgy process, facilitating their use in the sector

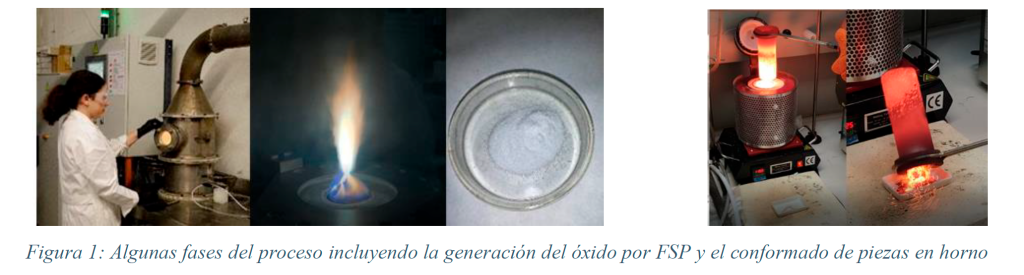

Figure 1: Some phases of the process, including creating oxide with FSP and shaping parts in a kiln

Thanks to the Reduce-Nano2.0 project, the bonds between the members of the project were made even tighter, which led to its exceptional progress through designing and optimising processes like i) producing nanoparticles based on metal oxides using FSP technology ii) extracting and purifying reducing agents based on lignin or ii) reducing the nanomaterials produced with FSP using lignin or melting agents as reducers. Extensive control and characterisation was done of the processes and the products obtained, and their environmental impact was also evaluated.

That is why the technical assessment of the project can be considered more than satisfactory, because the activities carried out made it possible, on one hand, to complete the production and characterisation of metal oxide based nanomaterials in its totality. On the other hand, it was possible to design and optimise a process for obtaining and characterising lignin that can be used as a reducer agent. Lastly, using metal oxide based nanomaterials and lignin based reducer agents made it possible to design and optimise chemical reduction processes to obtain interesting reduced nanomaterials. Additionally, experiments were done, even at a larger scale, for shaping test-tubes with the materials that were reduced. In short, the concept of the project was validated in terms of the transformation and creation of parts.

Thus, the results achieved make it possible to continue working along these lines of research to obtain metal materials with new properties.